COOPER GROUP

ROLLING THIN FILM OVEN

The Superpave PG binder specification looked for tests which would closely simulate field performance. Hotmix asphalt binder experiences significant aging during the manufacturing and laying process. Investigating this phenomenon within a laboratory environment, with a repeatable and simple test is very useful within the design process.

STAND ALONE 4 POINT BENDING BEAM

The CS-SA4PT-BB uses advanced servo pneumatic technology and a high-speed digital data acquisition and control system together with user-friendly software. During testing both graphical and tabular data are displayed on screen and test data is stored to disc in Microsoft® Excel® compatible format. The clamps are at 118.5mm (4.67 inch) centers (the distance between the outer clamps is 335.6mm (14 inches) according to AASHTO specifications but the height and width of the beam can be varied).

SUPERPAVE GYRATORY COMPACTOR

Superpave Gyratory Compactor is a high quality machine with which the user can easily and safely obtain accurate, repeatable results day after day.

Compaction is achieved by the application of a vertical stress (normally 600KPa (87psi)) via end platens to a known mass of asphaltic mixture within a 150 and 100mm (6 and 4inch) internal Ø mold. The longitudinal axis of the mold is rotated (gyrated) at a fixed angle to the vertical while the platens are kept parallel and horizontal.

HAMBURG WHEEL TRACKER

The Hamburg (Immersion) wheel tracking test is used to evaluate the resistance to rutting and moisture susceptibility of asphalt mixtures. AASHTO-T324 is the generally referred to test standard, although many states modify this procedure to meet their specific requirements. Outside of the US both AASHTO-T324 and EN12697-22 are followed.

What differentiates the Hamburg wheel tracking from other wheel tracking methods is the use of water to condition the temperature of the specimens rather than air.

TEXAS OVERLAY TESTER

The Texas Overlay Tester (CS-TOT) was designed to simulate the expansion and contraction movements that occur in the vicinity of joints or cracks and which result in reflection cracking in overlays. With the CS-TOT it is possible to characterize both the crack initiation and crack propagation properties of asphalt mixtures. Cox & Sons has developed the CS-TOT, which is a dedicated, state-of-the-art piece of equipment for carrying out this test.

BUDGET REQUEST

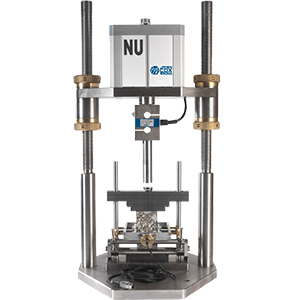

SERVO-PNEUMATIC UNIVERSAL TESTING

This machine is a development of the NAT which was developed by Keith Cooper and Professor Steven Brown at the University of Nottingham. The use of a high precision servo-pneumatic valve in conjunction with a low-friction actuator and sophisticated data acquisition and control, results in a performance that is equal to many servo-hydraulic systems.

BUDGET REQUEST

SERVO-HYDRAULIC UNIVERSAL TESTING

The Servo-Hydraulic Universal Testing Machine (CS-UTM-HYD) is a well-designed, inexpensive machine specifically developed for the testing of materials used in pavement construction. A motorized, adjustable crosshead reduces the time between test setups. The programmable temperature cabinet provides the possibility to perform frequency/temperature sweeps. Accurate waveforms are digitally generated and applied by the actuator producing repeatable conditions that are simulative of those created by moving or static vehicles.

Solicitar presupuesto

SERVO-HYDRAULIC UTM 100KN

The CS-UTM-HYD100 is a versatile universal testing machine designed and developed with the testing of pavement construction materials in mind. A hydraulically operated adjustable crosshead allows for quick and simple setup between tests.

BUDGET REQUEST